|

Functioning principle |

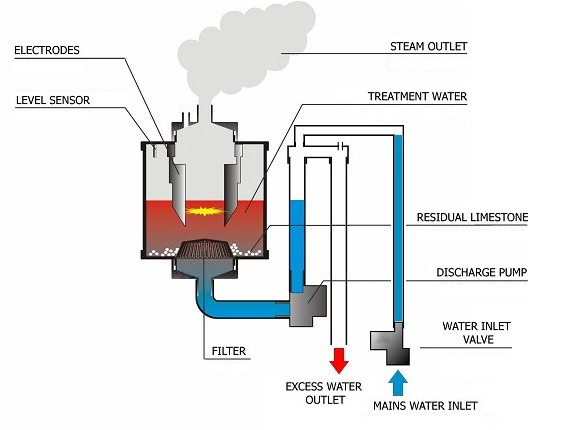

| The operation of EASYSTEAM series sunk-electrode humidifiers ia based on the conductivity of potable water to produce steam by boiling. A current is generated between the electrodes sunk in appropriate cylinder, that heats the water to boiling point. Current intensity (expressed in amperes) varies according to the quantity of water in cylinder that is in contact with the electrodes surfaces and the conductivity of the water itself. The electronics in the humidifier, via an amperometric transformer, measures current intensity and controls the water charge valve to raise the water level or the discharge pump to lower it. This system is fully automatic. Combined use of the microprocessor and a humidity sensor also makes it possible to set proportional functioning, optimising water and electricity consumption according to required humidity levels. In addition to ensuring functioning during steam output, the discharge pump also guarantees draining the cylinder completely when the unit has been idle for a set time: this prevents forming and depositing of limescale or other particles created during the boiling process. The EASYSTEAM series humidifiers are fully automatic and require only replacement of the cylinder when the electrodes are worn. The layout below illustrates the functioning principle of an immersed electrode humidifier. |

|

|

Applications |

|

• Air handling unit (AHU) |